- services@cardoxindia.in | cardoxindia@gmail.com

- Monday - Friday 9am - 5pm

Talk with Expert : +91 9321112606

Talk with Expert : +91 9321112606

The process is completely automated, allowing cleanout to take place without human entry into the silo or bin. It is a dry process meaning no water or other liquids are used. Therefore there is no water damage to the facility or surrounding areas. Clean upon easy and material within the silo is recoverable for further processing or load out. There is no contamination of the material plays for significant portion of the clean out project. Binwhip system is a mechanical cleaning system operated with hydraulic motor mechanical boom assembly, hydraulic operated motor moves inside the silo with specialized hose. It is operated at various RPM from 0 to 900 decided by the operator from Silo top. This is guided through mechanical boom with hydraulic controlling assy.The whole operation is controlled by single person from silo top. The end result is a clean vessel and reclaimed product.

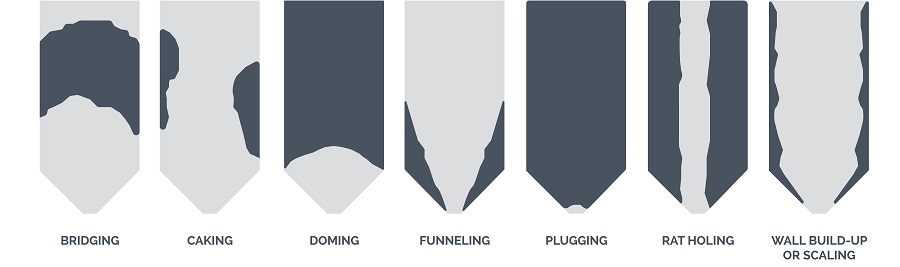

When dealing with bulk solids, product flow in the production line can't be ignored, Build-up, ratholing, bridging and plugging too after keep both the product and the profits in the bin.

BinWhip is valuable because it eliminates hassle and reduces costs. It takes care of flow problems quickly, minimizes down time, and keeps employees safe and on task. Results are measurable.

The BinWhip works from the top of the vessel, which eliminates the need for dangerous, confined space entry by employees. Video attached for reference.