- services@cardoxindia.in | cardoxindia@gmail.com

- Monday - Friday 9am - 5pm

Talk with Expert : +91 9321112606

Talk with Expert : +91 9321112606

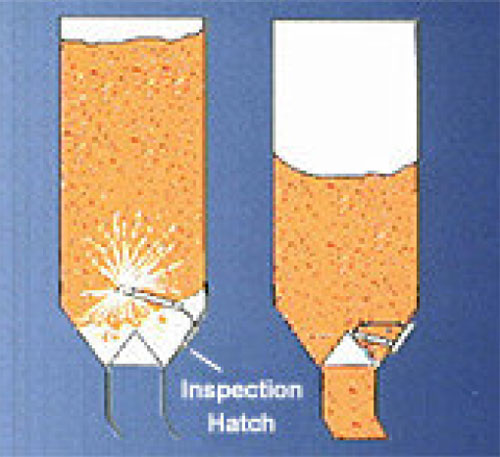

Before: Plug is removed to reveal build up of product

Cardox tube is placed in the tube holder, inserted and then secured in the socket. The tube is then activated.

After: The tube is removed to reveal build-up has been cleared and product is aerated and once again free flowing.

Cardox is widely recognised as the most efficient way and reliable means of clearing build ups and blockages...... whether grain, flour, maize, soya, salt, sugar, cement, gypsum, coal, fertilizer, catalyst, ores, powders etc. The powerful Cardox System provides the ultimate solution to clear even the most difficult of build ups.

Each and every time you use a Cardox Tube you instantly release a cold heaving mas of CO2 that expands 600 times its original volume!..... At pressures which can be regulated from 1,200 bar (18,000 psi) to 3,000 bar (40,000 psi).

Before: Plug is removed to reveal build up of product

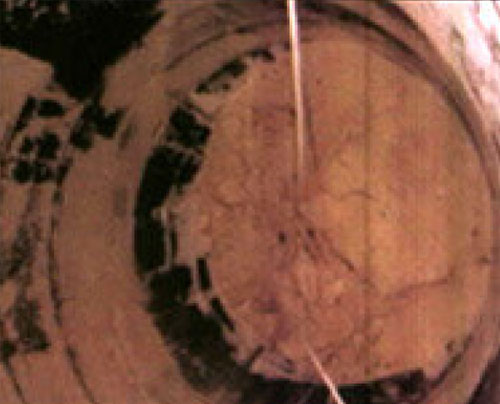

View of soya build up from down inside silo just prior to activation of one Cardox Tube.

Cardox Tube is activated, releasing within a second a powerful heaving mass of cold CO2 that expands 600 times its original volume.

Cardox clears the buildup and areates the product to produce a free flowing product.

Through sockets Through inspection Mounted onto silo wall

Through inspection Mounted onto silo wall hatches

Before: 15m high build up on walls of grain silo

After: One Cardox Tube clears the build-up

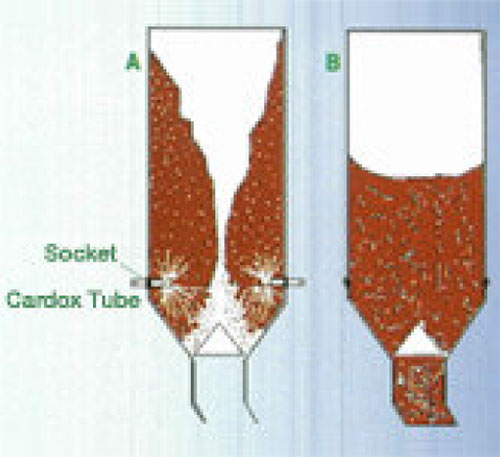

A

The 'Sealing Plug' is removed from the 'Socket' and a hole made in the product. The

Cardox Tube is inserted through the Socket into the product and activated.

B

Cardox Tube is removed and Sealing Plug replaced in Socket, returning the vessel to

normal operation until the next time Cardox is needed.

Cardox can be applied either through small Sockets mounted onto the vessel wall or through inspection hatches around the silo. Either way nobody need enter the vessel and Cardox Tubes can discharged away from the vessel area.

Compared to other methods of aerating product and clearing build-up Cardox usually proves more cost effective in terms of:

Capital costs – Many of our customers report that Cardox has paid for itself after just a single application.

Hire costs – Extremely reasonable rates available!

Running or operational costs – There are no continuous running costs with Cardox, the System need only be used when build-up accumulates.

Maintenance costs – Virtually no maintenance costs!

Cardox is available in the following options:

Purchase a complete Cardox System

Hire a Cardox System

Hire a Cardox Service Team to undertake the works

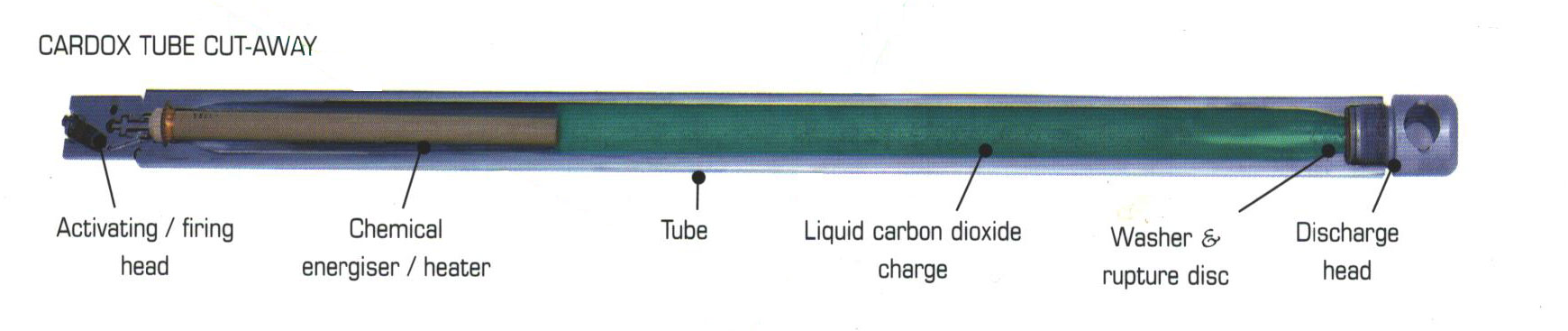

Cardox consists of a high strength reusable steel tube filled with liquid carbon dioxide, a chemical heater and a rupture disc.

When energised by the application of a small electrical charge, the chemical heater instantly converts the liquid carbon dioxide to a gas. This conversion expands the CO2 volume and builds up pressure inside the tube until it causes the rupture disc at the end of the tube to burst. This releases the CO2 - now 600 times the original volume - through a special discharge nozzle to create a powerful heaving force, at pressures up to 40,000psi (3,000bar). This all takes place in milliseconds.

Carbon dioxide gas is an inert gas that is commonly used in fire extinguishers, so it is safe to use without fear of generating secondary reaction with gases in the vessel/silo. In addition the quick release of the gas refrigerates the discharge, bringing it to a temperature low enough to avoid ignition of any air-gas mixtures inside the blocked vessel.

Simple, secure coupling devices are mounted on the equipment in areas of known build up, which allows you to set the Cardox Tube to a predetermined depth and discharge direction.