- services@cardoxindia.in | cardoxindia@gmail.com

- Monday - Friday 9am - 5pm

Talk with Expert : +91 9321112606

Talk with Expert : +91 9321112606

Cardox International Limited are the original manufacturers of the CARDOX SYSTEM which is used in a variety of industries in different applications

Cardox today, has grown worldwide with a presence in over 40 countries. In recent years, we have developed and grown our capability in both resources and equipment since our product was first launched in 1914. Our goal is to be the premier global solution provider in the Bulk Material and Civils industry.

Cardox India Private Limited is a Private incorporated on 20 October 2005. It is classified as Non-govt company and is registered at Registrar of Companies, Mumbai. Its authorized share capital is Rs. 1,000,000 and its paid up capital is Rs. 200,000. It is inolved in Renting of construction or demolition equipment with operator.

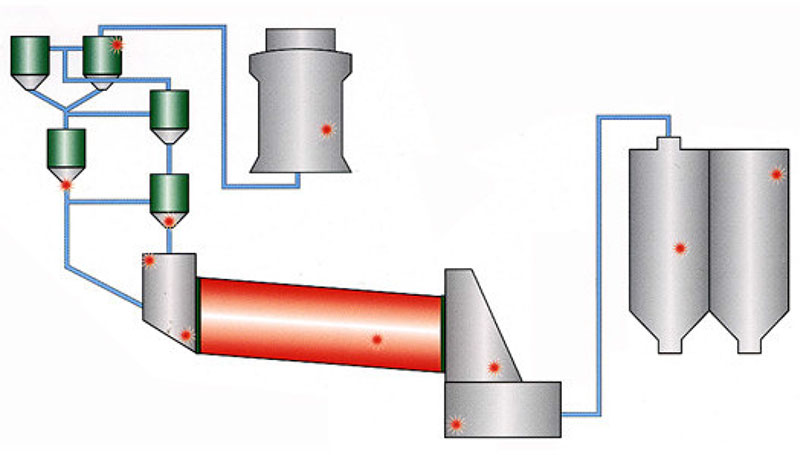

Cardox can quickly remove blockages and build-ups and restore plant production to optimum levels... with no need to sit through an extended shut down while the equipment cools. Cardox can be used in ALL areas of the processing lines at operating temperatures.

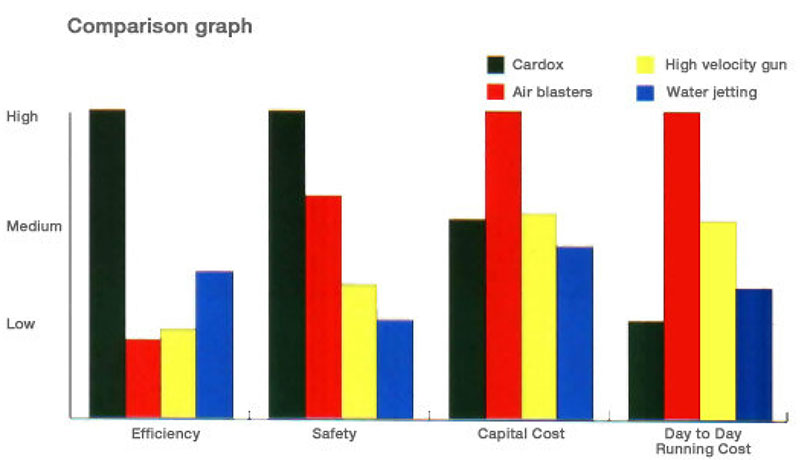

Unlike airblasters where cement plants complain of ineffectiveness and report losses of efficiency of up to 75%, using Cardox there is NO loss in efficiency! Each time you use a Cardox Tube you are guaranteed maximum pressure to remove the build-up and with tubes having a working life of over 15 years, maximum efficiency is achieved over that period.

With a safe and powerful carbon dioxide blast, one quick Cardox Tube can remove tons of build up. Three or four Tubes and you're back up to running at full capacity, with little, or no down time, no added cost and no time to come back up to full temperature.

Before: Opening inspection holes reveals build-up of cement.

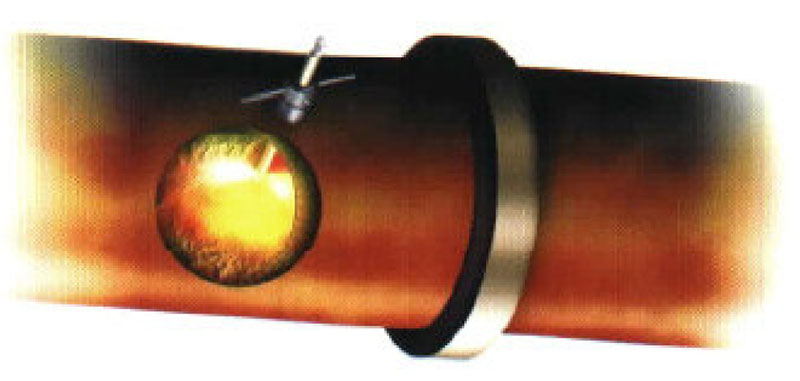

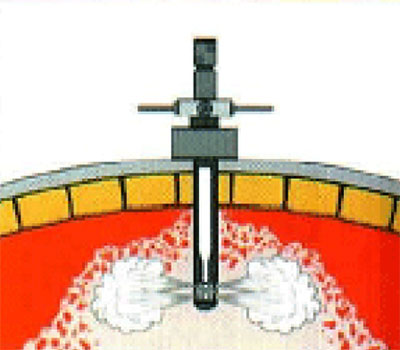

During: Cardox Tube is inserted into the build-up through special sockets.

After: In seconds the Cardox Tube is activated and removed to reveal the kiln running at full production.

Cardox is safely used from the outside of all areas of the processing line. Since workers do not have to enter the kiln or any part of the production line, there is no danger of exposure to heat or contaminated air, and there is no danger of loosened material falling on your employees, which may harm or even bury them.

The Cardox tube is secured in a sealed coupler assembly. This means that you operators are not exposed to flying debris - unlike water injection... or in danger of being too close to the blast area - as with shot gun methods. Plant personnel operate from a safe distance whilst the Cardox Tube does the work.

No other method of clearing build-ups in your production line is safer, easier or more cost effective than the Cardox Blockage Clearing System!

Other ring or blockage removal operations, such as sending workers inside, may take as long as eight days and up to thirty workers and involves shutting down the kiln and allowing it to cool off. This wastes time and of course money.

The Cardox System can have the problem fixed in a matter of hours, requiring only one or two workers.

Compared to manual cleaning techniques or plant shut downs the Cardox Blockage Clearing System can typically pay for itself in a single application.

Many cement plants are beginning to realise just how costly the day to day running costs of airblasters can be! Add on the high installation costs, the high equipment costs and indeed the maintenance costs required with airblasters and it is no wonder CARDOX is becoming known as the most cost effective method of removing blockages and build-ups.

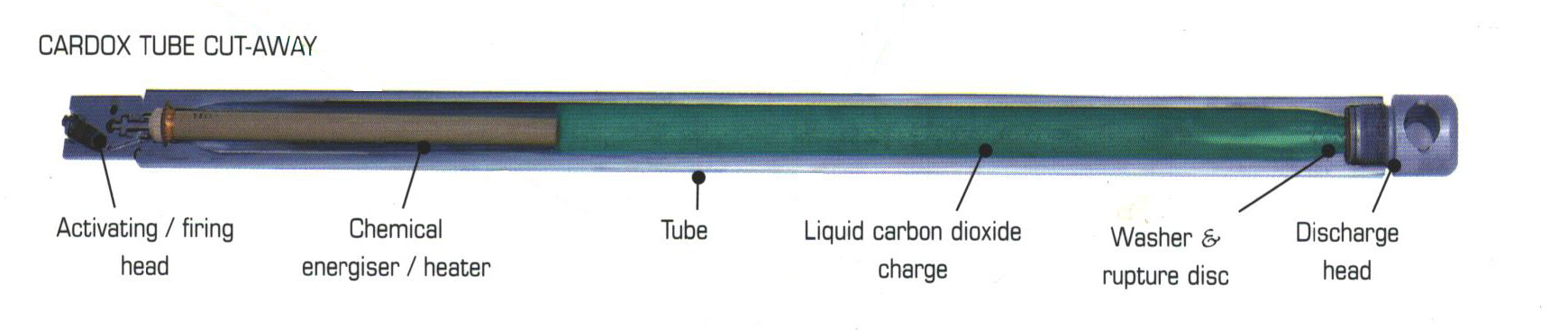

Cardox consists of a high strength reusable steel tube filled with a liquid carbon dioxide, a chemical heater and a rupture disc. When energised by the application of a small electrical charge, the chemical heater instantly converts the liquid carbon dioxide to a gas. This conversation expands the CO2 volume and builds up pressure inside the tube to burst. This releases the CO2 - now 600 times the original volume - through a special discharge nozzle to create a powerful heaving force, at pressures up to 40,000psi (3,000bar) Cardox can dislodge over 3 tons of blockage in a single blast. This all takes place in milliseconds.

Carbon dioxide gas is an inert gas that is commonly used in fire extinguishers, so it is safe to use without the fear of generating secondary reactions with gases in the processing line. In addition the quick release of the gas refrigerates the discharge, bringing it to a temperatre low enough to avoid ignition of any air-gas mixtures inside the blocked vessel.

Simple, secure coupling systems are mounted on the equipment in areas of known build up, which allows you to set the Cardox Tube to a predetermined depth and discharge direction. This control of the discharge minimises any risk to refractory in the equipment.

After use the Cardox Tube is easily removed and replaced with a Sealing Plug that returns the equipment back to normal operation until the next time Cardox is needed.

Cardox Tube Cut-away

Cardox Tubes are refilled and reused continually for over 15 years.

With the new Tube Recharging Unit, Tubes are refilled with liquid CO2 in less than a minute.